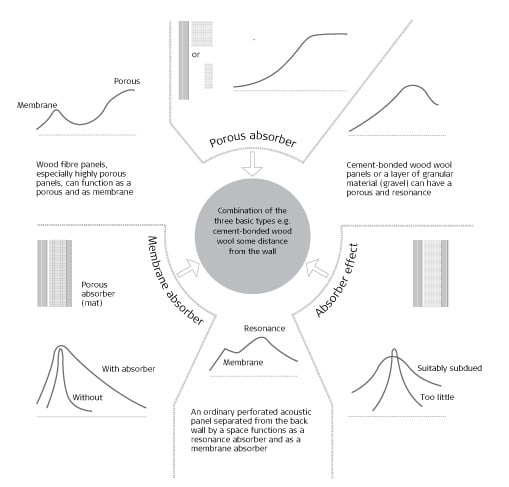

The three main types of absorbers (porous absorbers, membrane absorbers and resonance absorbers) can be combined to obtain a predetermined reverberation time, one which is balanced in terms of the various frequencies.

Often it is enough to combine two types, for example a porous absorber and a membrane absorber.

It is very important to try and arrive at a reverberation time which is the same for the entire frequency range. Together with the shape of the room and how the sound absorbers are distributed, the balanced reverberation time is of critical importance for the overall acoustic comfort, which is the final goal.

Room acoustic problems arise when the reverberation time is not uniform across the different frequency bands. The following section presents the three absorber types which – in the right context – can balance the reverberation time and provide a comfortable acoustic environment.

It is important for acoustic quality that the chosen reverberation time is as independent of the frequency as possible. This basically means that if you have chosen a reverberation time of, for example, 0.6 seconds, then this must in so far as possible be the same for the bass, mid-range and treble frequencies. Measuring the reverberation time in a given room will very easily reveal any problems. Many of the room acoustic problems one experiences stem from the fact that this balance has not been addressed. Often, the reverberation time is longer in the bass range than in the other frequency ranges. In other words, the sound-absorbing materials are frequency-dependent in their effect. The result can, in certain cases, produce an unpleasant, roaring sound in the room, in other words a lack of acoustic comfort.

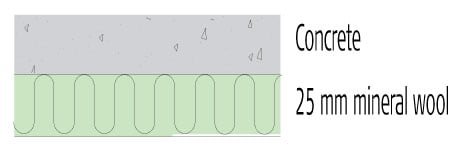

For example: Residential concrete tower block buildings from the 1970s can give this experience if, for example, you sit down in a corner sofa in the living room. The bass tones in speech and music sound strange. Well-known sound absorbers such as mineral wool etc. are most effective in the mid-range and treble frequencies. So if you only use materials like this in your project, you can encounter the problems described above with prolonged reverberation times in the bass. In many types of buildings, the problem with the bass tones can be solved by combining two sound absorbers, for example by installing 25-millimetre Troldtekt with a 250-millimetre mineral wool backing. As we will see in the following, it is not only the choice of material, but also the way in which the material is installed that determines its absorption effect. We will take a closer look at the different absorber types and their characteristics. There are three main types; see Figure 1.

Porous Absorbers

These materials consist, as the name suggests, of porous material. Mineral wool, textiles, clothing, curtains, carpets and certain types of foam plastic all fall into this category. The sound-absorbing effect stems from the fact that the sound energy can penetrate the material on hitting the surface. Here, the sound energy is converted into heat energy, so that only a small part is reflected in the form of sound energy. In other words, the material has absorbed some of the sound. As a sound absorber, Troldtekt is a combination of a porous absorber and a resonance absorber (as described below). As we all remember from our schooldays, energy can never come into existence or disappear – it can only be transformed. In porous absorbers, sound energy is converted into heat energy.

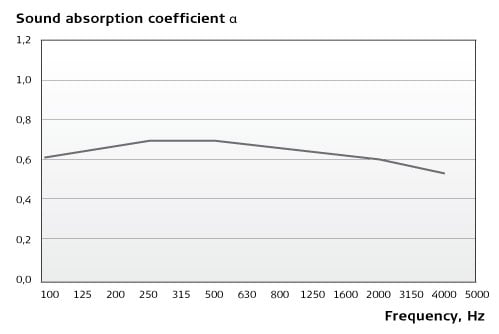

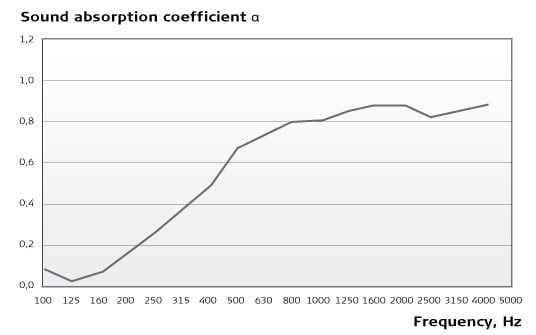

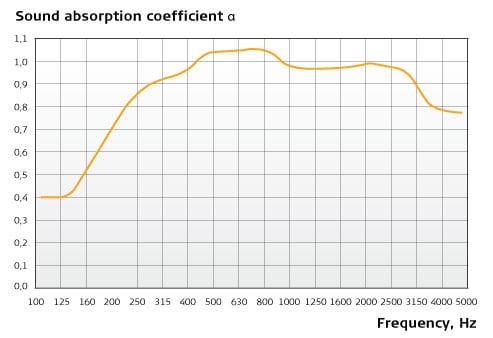

However, do not imagine that you can exploit this for the purpose of heating the room. The amounts of energy here are negligible – a mere one millionth or a billionth of a watt. As mentioned above, porous absorbers are most effective for the mid-range and treble tones, and the sound absorption coefficient is usually as shown in Figure 9.

Figure 9: Porous absorbers

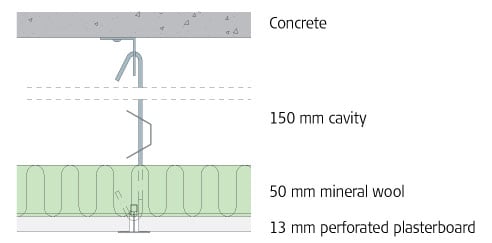

As you can see, the porous absorber – where it functions best – is very effective, with sound absorption coefficients of up to 100 per cent, in other words completely absorbent. On the other hand, the effect decreases towards the lower frequencies, and with the bass tones it hardly functions at all. It is important to note that the same porous material, for example a 50-millimetre soft mineral wool batt, will be more or less effective depending on how the mineral wool batt is installed. The thicker the material, and/or the further away from the ceiling or wall it is mounted, the better it works. See Figure 10.

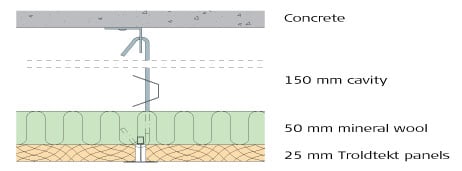

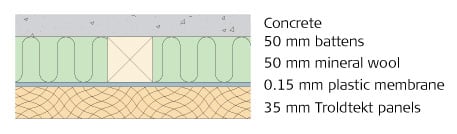

Figure10:

The optimum distance between the fixed ceiling and a suspended acoustic mineral wool ceiling is in practice 200-300 millimetres. Structures such as these are effective down to approx. 200 Hz. Note: 35-millimetre Troldtekt panels with a 50-millimetre mineral wool backing produce about the same result as a suspended ceiling. See Figure 11.

Figure 11:

Membrane Absorbers

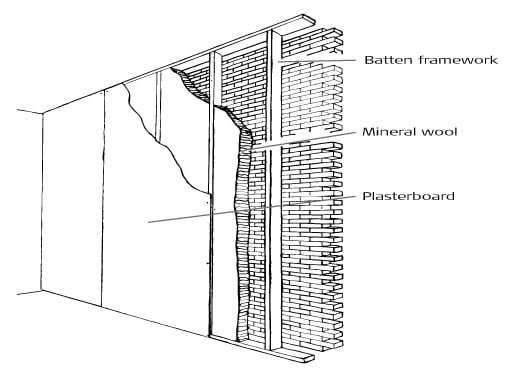

In the bass frequency range, it is necessary to consider other types of absorbers, in particular membrane absorbers which are proper bass absorbers. They constitute an important group absorbers for several reasons, but they are often overlooked, perhaps because they do not look as though they can absorb sound. Basically, the membrane absorber is a flat box, 100-200 millimetres deep, mounted on the wall with a thin sheet of plywood or similar on the front and with a light mineral wool filling the box cavity. See Figure 12.

Figure 12: Membrane absorber, plasterboard wall

If you softly bang the front panel with your hand, you will hear a deep tone, a bit like a bass drum, though much weaker. The tone you hear is the resonance frequency of the oscillating system which consists of the front panel with a certain mass combined with the spring that is formed by the trapped air.

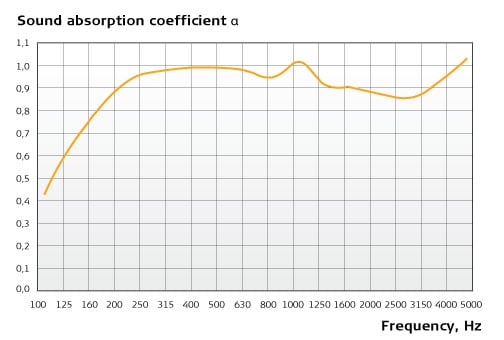

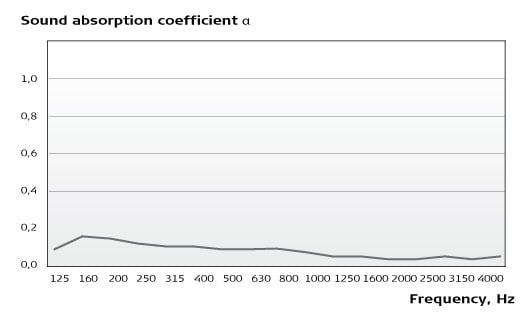

The resonance frequency is also the frequency at which the membrane absorber absorbs, as sound energy causes the membrane to oscillate. In other words there is an energy transformation, but this time from sound energy to mechanical oscillatory energy. Thus, the first significant characteristic of the membrane absorber is that it absorbs sound energy at low frequencies. See Figure 13.

Figure 13: Membrane absorber, parquet floor on joists

The second key characteristic of the membrane absorber is that it is a common feature, as it were, of our day-to-day life, as ordinary building components such as doors, windows, wood floors (on joists) and plaster walls all function as membrane absorbers. The sound absorption coefficient is not staggering, perhaps 15-20 per cent, but, as the components together constitute a significant area, the effect is significant. Take for example the large areas of glass in many modern buildings. They lead to many problems with the indoor climate, but as far as the acoustics are concerned, they ensure that the reverberation time does not increase outrageously for the bass tones. Because they are membrane absorbers, the glass sections help to balance the room’s acoustics. Try banging your hand gently on a large windowpane, and notice how deep the sound is which is produced. It is in this frequency range that the window is absorbent. However, bear in mind that membrane absorbers only work for bass tones, and therefore reflect higher frequency sounds. Windows can therefore produce uncomfortable reflections or echo effects which have to be counteracted in some other way. It is also useful to know that wood floors on joists, which are, of course, membrane absorbers, can produce additional drum sounds – in other words noise which occurs when walking in the floor in the same room. If this is a problem, try laying a carpet or placing rugs on part of the floor. This may well be necessary in large, open-plan offices for example.

Resonant Absorbers

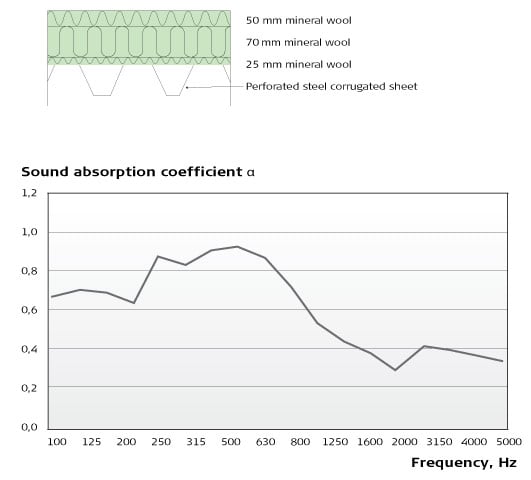

The third main type is resonance absorbers. They work on the same principle as when you blow across the mouth of a beer bottle to produce a note. The tone occurs when the oscillating system, which comprises the air in the bottleneck, oscillates on the spring formed by the air in the bottle. The mechanism is called a Helmholtz resonator, and you find it in many systems, among other things clarinets, hydraulic silencers and ventilation ducts. As with the membrane absorber, the resonance frequency you hear is the frequency which is absorbed, as there is an energy transformation from sound energy to mechanical oscillatory energy. In its pure form, the absorber would only absorb one frequency, which would not be very practical as regards room acoustics (but very effective in, for example, hydraulic silencers). Real acoustic resonance absorbers take the form of, for example, perforated plasterboard, perforated metal corrugated sheets and metal boxes. Here, the holes in the surface correspond to the bottleneck, and the space behind the sheet to the bottle container. See Figure 14.

Figure 14: Typical perforated steel corrugated sheet

Perforated plasterboards are usually combined with a porous absorber in the cavity behind the plasterboard and/or a thin layer of felt immediately behind the board. As the plasterboard also functions to some degree as a membrane absorber, it normally covers over a wide range. See Figure 15.

Figure 15: Typical perforated plasterboard