Product Description

Owens Corning 703 series acoustic insulation (also called rigid fiberglass) is the #1 global material for in-frame absorption as well as building acoustic panels and bass traps. It’s used by top brands like Nankarrow, Acoustimac, Auralex, Acoustical Surfaces, Real Traps, GIK Acoustics, etc. and is also recommended by top global acoustic consultants. It is stiff enough to be easily wrapped without requiring to be framed using an edge hardener yet it is very easy to cut into shape. It is ideal for DIY acoustic panels or fiberglass acoustic panels.

Combine two layers to make broadband panels for your studio or home theatre. Place one acoustic panel in every reflection point in your room. Typically the critical reflection points are the 2 spots to the side of each speaker, the ceiling directly above the speakers and the opposite wall to the speakers (behind listening area). We would also recommend that you place more acoustic panels every 2 feet thereafter to get the best absorption possible.

Owens Corning® Types 703 & 705 700 Series® Fiberglass Insulation™ Boards are made of inorganic glass fibers with a thermosetting resin binder and formed into rigid boards.

Owens Corning 703 Fiberglass Acoustical Board is the preferred product for use as the core insulation for acoustical wall and ceiling panels. The reasons for the popularity of the 703 Fiberglass panels mainly has to due with the panels ability to absorb both Mid and High range frequencies while being lightweight, rigid, and economically priced. Owens Corning 703 Fiberglass Acoustical Board is made of 48kg/m3 density fiberglass which allows the panels to be both lightweight and rigid. 2″ 703 Fiberglass Board is very good at absorbing both Mid and High range sound frequencies which makes it the ideal product for Acoustical wall / ceiling panels. When you double them up (4″), they become effective upto 100Hz. At three layers (6″) they can absorb down to 70Hz. So 703 Fiberglass panels should be stacked to create thicker panels to better absorb low frequencies in Bass Trap applications.

2″ Owens Corning 703 Fiberglass panels are usually inserted into a 2ft x 4ft frame and then wrapped with acoustical transparent fabric and fastened to walls/ceilings with panel hardware. The 2″ 703 panels can also be used to make frameless acoustical panels. Coat the perimeter edges and 4 corners of the fiberglass with an edge hardener, wrap the fabric directly over the fiberglass panel.

Features:

- Excellent acoustic absorption

- Save and reduce heat transfer, lowering operating costs

- Resists damage and maintains structural integrity and efficiency

- Efficiently reduces sound transmission

- Owens Corning 700 series is lightweight, resilient, easy to handle and fabricate on the job site

Specifications:

- Thickness: 2 inch (50mm)

- Density: 48 kg/m3 (703)

- Panel Size: 4ft x 2ft (1200mm x 600mm)

- Panels per Box: 6 Panels

- Coverage per Box: 48 square feet

Acoustic Performance in 1/3 Octave Bands

Installation Information

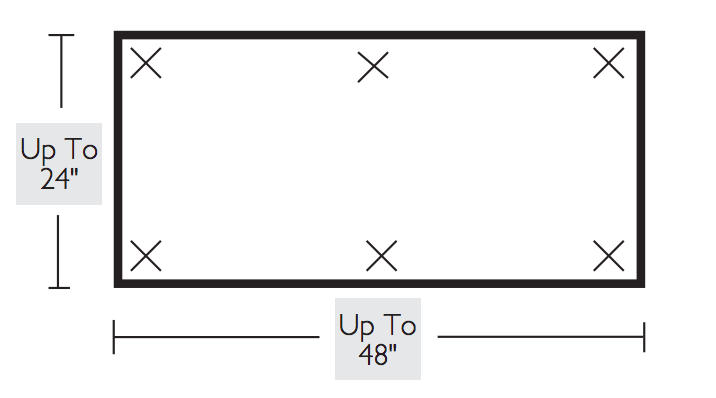

OC Type 703 can be easily cut with a knife and fit neatly into irregularly shaped areas. Fasteners shall be located not less than 3″ (75mm) from each edge or corner of the board. Pin spacing along the equipment should be no greater than 12″ (300mm) on centers. Additional pins or clips may be required to hold the insulation tightly against the surface. Weld pin lengths must be selected for tight fit but avoid “oil-canning.”

For Vertical Applications

Type 703 can be installed between furring strips, hat channels and Z-shaped furring where a finish will be applied.

For exposed applications

The product can be impaled on impaling pins or adhered with adhesive.

For Horizontal Applications

Type 703 can be installed on horizontal surfaces by using impaling pins.

On Masonry Construction Type 703 and Type 705 can be installed on the interior face with Nankarrow ProPin self adhesive impaling pins, or by using appropriate adhesives. Lengths should be selected for tight fit. Protect pin tips where subject to contact. Pins should be located 3″-8″ from the edge(s) of the board.

Ajit Kumar –

I purchased these to make 4″ acoustic panels for my stereo listening room. The fiberglass boards arrived in perfect shape and were actually very clean and easy to work with. I covered my panels with Nankarrow Breathe fire rated fabric and they look simply stunning. But more importantly, they perform amazing! If you place these strategically to eliminate early reflection points, you will be surprised at the results you can attain. Everything just sounds so much cleaner and the ringing and flutter has been greatly if not completely reduced. Topped with the black fabric, the panels look amazing and blend in to my room very well. Turns out you can have both aesthetics and performance!

(0) (0) Watch Unwatch

Iqbal Khan –

Very nice product. Aural exchange has taken all precautions for packaging and safe delivery. Regarding the owens corning 703 fiberglass it is really a very nice product for home theatre use. I am fully satisfied with the product.

(0) (0) Watch Unwatch

Harsh Kherwal –

This is the product that I Used In My Own Home Studio. Now I don’t have to worry about the Formaldehyde and other toxic air particles in my room. This is clean.

(0) (0) Watch Unwatch

Pinaki Laskar –

I have made over 100 extremely professional acoustic panels using this material for my friends and clients. Never been disappointed. I’ve used Rockwool as well and definitely feel that this performs so much better at 4 inch thickness (2 layers). As someone else has mentioned, it’s used commonly in USA by top acoustic companies and I’d like to thank Aural Exchange for bringing the product in India.

(0) (0) Watch Unwatch

Prashant Awasthi –

Picked this up because it’s the material of choice for many top companies including GIK Acoustics. Thanks for making it available all the way in Lucknow! The panels are performing beautifully and the 703 panels are absolutely non itchy.

(0) (0) Watch Unwatch

Shezan Shaikh –

I’m extremely pleased with the OC 703 acoustic panels. I have used them for making bass traps and 50mm panels I’ve just installed. They have absolutely transformed the sound of the room—and they look premium – dark brown! I almost didn’t want to cover the panels with fabric.

(0) (0) Watch Unwatch

Shashank Ketkar –

At this price it was a steal deal for me. Top quality and non-itchy.

(0) (0) Watch Unwatch

Ratnakar Dubey –

Excellent service from Aural exchange and the product has done the job nicely.

(0) (0) Watch Unwatch